Key Takeaways

- Sculpting falls into three core approaches: additive, subtractive, and casting.

- Additive sculpting builds up material (clay, wax, polymer) and is great for rapid form exploration.

- Subtractive sculpting removes material (stone, wood, ice) and demands precise tool control.

- Casting captures a model in a mold and reproduces it in durable media such as bronze or plaster.

- Choosing the right type depends on material preference, scale, budget, and the artist’s workflow.

Ever walked into a museum and wondered why some statues look like they were chiseled from a single block while others appear to be poured from molten metal? The answer lies in the three fundamental ways artists shape three‑dimensional art. Understanding three types of sculpting helps beginners pick a path, lets seasoned makers refine their process, and gives collectors a clearer lens for evaluating work.

What Is Sculpture?

Sculpture is a three‑dimensional art form that manipulates solid material to create a physical object that can be viewed from any angle. It spans millennia, from the limestone busts of ancient Egypt to the hyper‑realistic resin figures of today. While the end result is a tangible object, the journey to that object diverges into three distinct techniques.

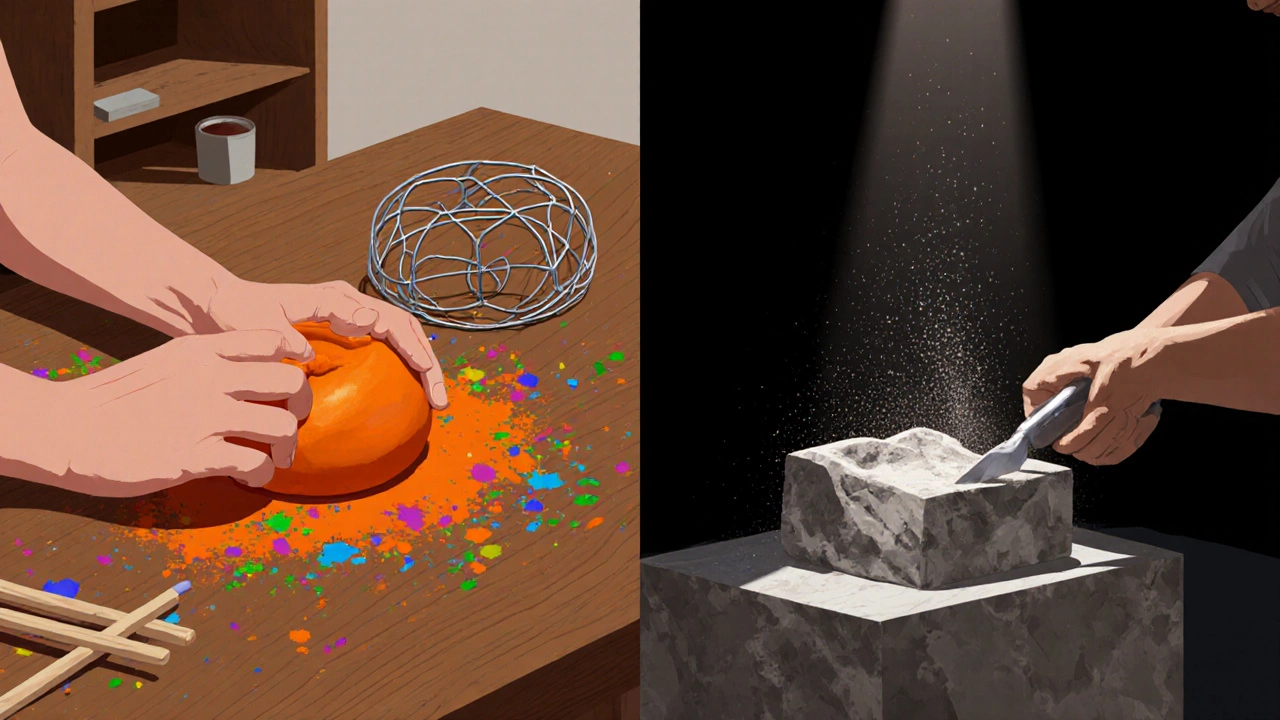

1. Additive Sculpting - Building Up the Form

Additive sculpting is the process of layering material to create a shape. Artists start with a pliable medium-clay, wax, polymer clay, or even digital 3‑D printing material-and repeatedly add mass until the desired volume emerges.

Typical materials: oil‑based clay (e.g., Plasticine), water‑based porcelain clay, wax for lost‑wax casting, polymer clay (Sculpey, Fimo).

Core tools: wooden modeling sticks, steel spatulas, loop tools, ribs, and wire armatures for support.

Because the material stays soft, adjustments are easy. An artist can push, pull, smooth, or scrape without committing to a cut. This flexibility makes additive sculpting ideal for expressive, gestural works and for creating an original model that will later be cast in bronze or resin.

2. Subtractive Sculpting - Carving Away the Unwanted

Subtractive sculpting involves removing material from a solid block. The artist’s vision is already present inside the raw mass; the challenge is to liberate it.

Typical materials: marble, limestone, wood (basswood, oak), alabaster, ice, and even synthetic blocks like engineered stone.

Core tools: point chisels, tooth chisels, flat chisels, rasps, mallets, pneumatic rotary tools, and sandpaper for finishing.

Because each strike is irreversible, subtractive sculptors plan meticulously, often sketching full‑scale drawings or creating small maquettes first. The method is celebrated for its crisp lines, fine detail, and the timeless quality of stone.

3. Casting - Turning a Model into a Durable Replica

Casting captures a three‑dimensional form in a mold and then pours a liquid medium into that mold to create a solid copy. The original model can be made by additive or subtractive means; the cast is the final product.

Common casting processes:

- Lost‑wax (cire‑perdue): a wax model is encased in a refractory plaster, melted out, and replaced with molten bronze.

- Plaster casting: a silicone or rubber mold receives liquid plaster, producing a lightweight replica.

- Resin casting: epoxy or polyester resin cures inside a silicone mold, popular for small figurines.

Typical materials for the final piece: bronze, aluminum, iron, plaster, resin, concrete, and even glass.

The advantage of casting is repeatability. An artist can produce editions, each numbered and signed, making larger distribution feasible while preserving the original’s integrity.

Comparison Table: Additive vs Subtractive vs Casting

| Aspect | Additive | Subtractive | Casting |

|---|---|---|---|

| Primary Material | Clay, wax, polymer | Stone, wood, ice | Bronze, plaster, resin |

| Process | Build up mass layer by layer | Remove mass with tools | Create mold → pour liquid → solidify |

| Typical Tools | Modeling sticks, armature wire | Chisels, mallet, rotary tools | Molds, crucibles, pouring ladles |

| Finish Options | Smoothing, firing, patina after casting | Polishing, sandblasting, acid etching | Patina (metal), painting (plaster), polishing (resin) |

| Common Artists | Auguste Rodin (modeling), Henry Moore (clay maquettes) | Michelangelo (marble), Donatello (bronze but carved wax) | Louise Bourgeois (bronze casting), Anish Kapoor (large cast steel) |

Historical Highlights of Each Type

Understanding how each technique evolved offers clues about why certain styles dominate certain eras.

Additive: Early humans molded clay figurines like the Willendorf Venus (c. 28,000 BC). In the Renaissance, masters such as *Donatello* used wax models before bronze casting, allowing intricate detail that carving alone could not achieve.

Subtractive: The ancient Greeks perfected marble carving; the Parthenon Frieze remains a benchmark of subtractive mastery. Michelangelo’s *David* (1504) exemplifies how a single block can conceal a masterpiece waiting to be freed.

Casting: The lost‑wax method traces back to Mesopotamia (c. 3000 BC). In the 19th century, the Industrial Revolution made large bronze foundries affordable, leading to public monuments by artists like *Auguste Rodin*.

Choosing the Right Technique for Your Project

When you start a new sculpture, ask yourself these practical questions:

- What is my budget? Additive works require cheap, reusable clay; stone carving can become pricey due to material and waste.

- Do I need multiples? If I plan an edition, casting is the only realistic path.

- What scale am I targeting? Large outdoor works often start as a small additive maquette, then are scaled up via casting.

- How much time can I devote? Subtractive sculpting demands longer setup and tool maintenance.

- What finish do I envision? Metal patinas versus polished stone surfaces shape the final aesthetic.

Answering honestly narrows the field, letting you focus on the tools, materials, and safety precautions specific to that technique.

Practical Tips & Common Pitfalls

- Armature First: For additive pieces that exceed a few inches, build a sturdy wire armature to prevent sagging.

- Tool Maintenance: Sharpen chisels regularly; a dull edge slips, increasing the risk of accidental cracks.

- Mold Release: When casting, apply a proper release agent; otherwise the cast will stick and the mold may tear.

- Safety Gear: Wear respirators when sanding stone, gloves when handling hot metal, and eye protection during carving.

- Test Swatches: Before committing a whole block, carve a small scrap to gauge stone grain and tool response.

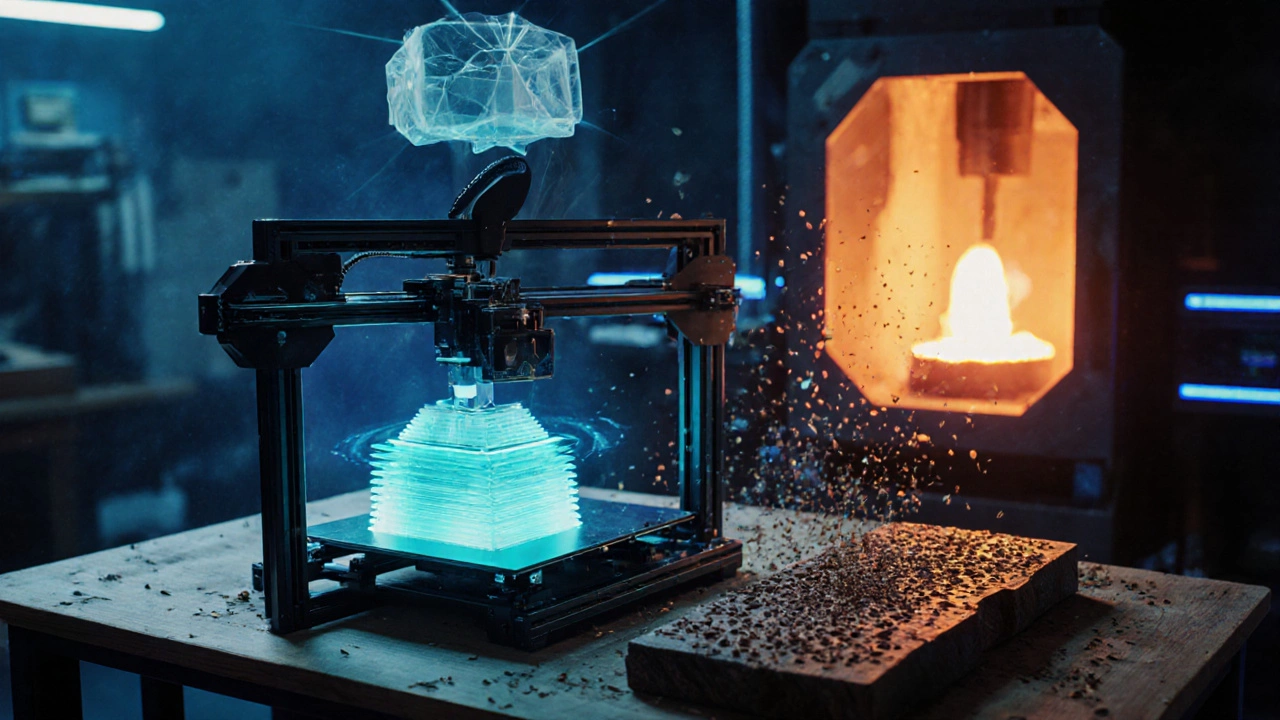

Future Trends in Sculpting Techniques

Digital tools are blurring the lines between the three classic types. 3‑D printers now layer polymer resin (additive) to produce objects that can later be sanded like carved stone, while CNC routers perform subtractive cuts based on digital models. Artists combine these methods, creating hybrid works that start as a digital design, get printed, then cast in metal.

Expect to see more "digital‑first" studios where the initial concept lives entirely in software, then materializes through a mix of additive, subtractive, and casting processes.

Frequently Asked Questions

Can I combine additive and subtractive methods in one piece?

Absolutely. Many sculptors carve a rough stone form (subtractive) and then add fine detail with clay or wax (additive) before casting the whole piece. This hybrid approach maximizes the strengths of each technique.

Is casting only for metal?

No. While bronze and iron are classic casting media, artists also cast plaster, resin, concrete, glass, and even edible materials like chocolate. The choice depends on the intended environment and budget.

What safety precautions should I take when carving stone?

Wear a dust mask or respirator to avoid inhaling silica particles, use hearing protection, keep your tools sharp, and work in a well‑ventilated space. A sturdy bench and clamps prevent the stone from shifting unexpectedly.

How long does a bronze casting process usually take?

From wax model to final patina, expect 2-4 weeks. Wax carving takes a few days, mold making another week, followed by bronze pouring, cooling, metal chasing, and patina application.

Which technique is best for beginners?

Additive sculpting with polymer clay is the most forgiving. The material is cheap, resets with the oven, and mistakes can be smoothed out before the piece hardens.

Next Steps for Aspiring Sculptors

Pick a medium, set up a safe workspace, and commit to a small project. For additive beginners, try a simple torso in polymer clay, bake it, and experiment with surface finish. If you’re drawn to stone, start with a soft limestone block and practice basic chops before moving to marble. Those intrigued by casting can partner with a local foundry to produce a limited‑edition bronze of an already‑finished wax model.

Join local art groups, attend workshops, and document each step. The more you experiment, the clearer your preferred sculpting type will become.

Remember, the three types of sculpting are not rigid categories but tools in an artist’s toolbox. Mastery comes from playing with each, understanding their strengths, and letting the idea dictate the method.